What is CLT

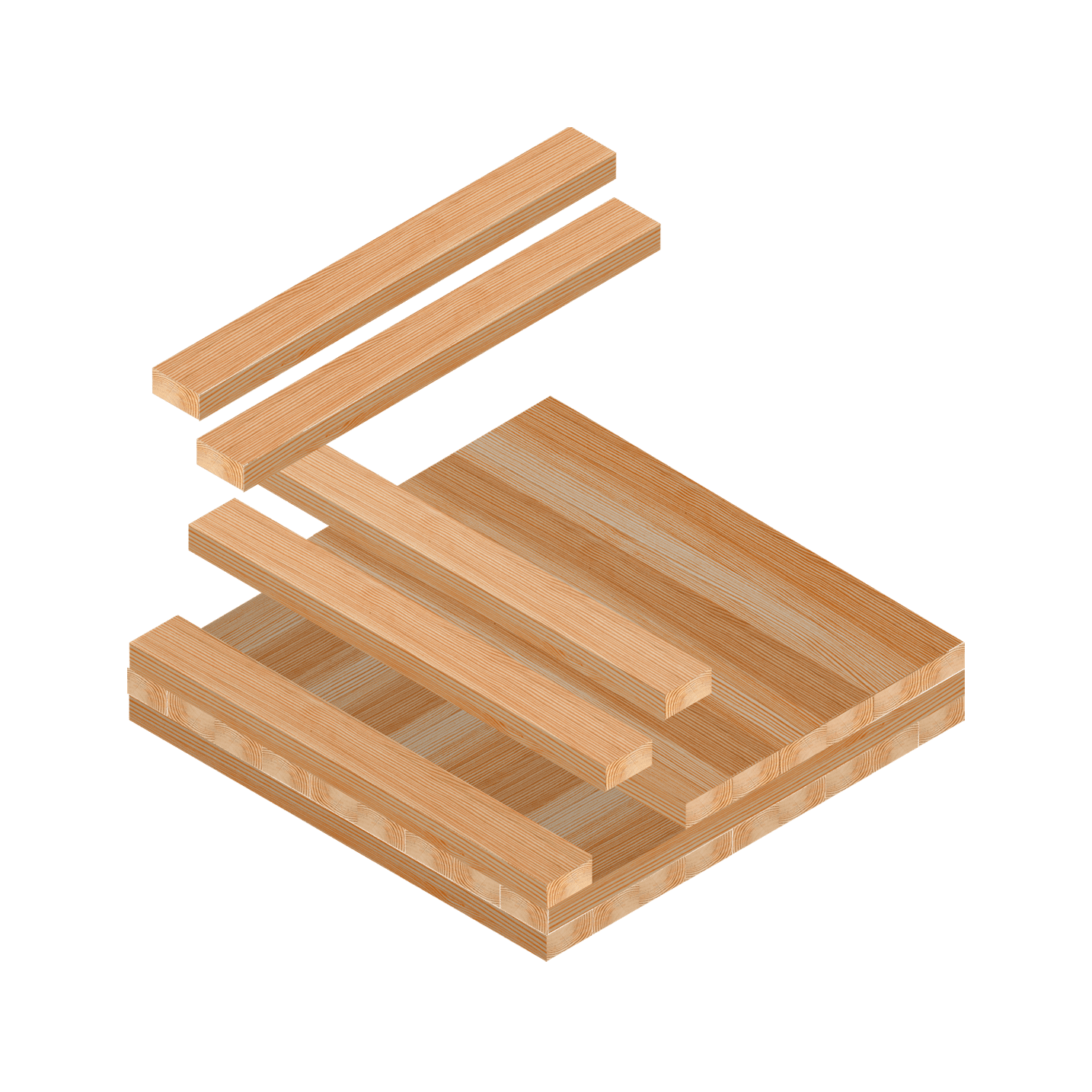

Cross-Laminated Timber (CLT) is an engineered wood product that is composed of multiple layers of solid wood boards or lamellae, which are stacked in alternating directions and bonded together with adhesive. This unique layering and bonding process gives CLT its exceptional strength and versatility, making it a popular material in modern construction. Here's how CLT is typically made: Material Selection: CLT is primarily composed of softwood species such as spruce, pine, or fir. The choice of wood species may vary depending on the region and project requirements. It's essential to use high-quality wood with minimal defects for CLT production. Drying: The selected wood is kiln-dried to reduce its moisture content to the desired level, typically around 12-15%. Proper drying is essential to prevent warping and ensure the stability of the final CLT panels. Lamination: Once the wood is dried, the boards or lamellae are planed to a uniform thickness. These lamellae are then stacked in layers, with each layer's grain direction oriented perpendicular to the adjacent layer. The number of layers may vary based on the desired thickness and strength of the CLT panel. Adhesive Application: A layer of structural adhesive, usually a formaldehyde-free polyurethane adhesive, is applied between each lamella layer. This adhesive bonds the layers together to create a solid, composite structure. Pressing and Curing: The stacked layers are placed in a hydraulic press, where they are subjected to high pressure and temperature. This process cures the adhesive, creating a strong bond between the layers. The pressing time and pressure can vary depending on the manufacturer and panel thickness. Trimming and Cutting: After curing, the CLT panels are trimmed to the desired dimensions and cut into specific shapes as needed for the construction project. Openings for doors, windows, and other architectural features can be precisely cut into the panels during this stage.

Quality Control: Quality control checks are performed to ensure that the CLT panels meet the required standards for strength, dimensional accuracy, and surface quality. The resulting CLT panels are solid, stable, and can be used for various structural elements in buildings, including walls, floors, roofs, and more. CLT's dimensional stability and excellent load-bearing capacity make it a sustainable and innovative choice for modern construction, offering benefits such as reduced construction time, lower environmental impact, and design flexibility.

Benefits about CLT

Cross-Laminated Timber (CLT) offers a wide range of benefits that have made it increasingly popular in the construction industry. Here are some key advantages of CLT: Sustainability: CLT is a sustainable building material made from renewable resources—wood. It has a lower carbon footprint compared to traditional construction materials like concrete and steel. Using CLT can contribute to reducing greenhouse gas emissions and promoting eco-friendly construction practices. Strength and Stability: CLT panels are incredibly strong and stable due to their crosswise layering. They exhibit excellent load-bearing capabilities, making them suitable for a wide variety of structural applications, including tall buildings. Lightweight: CLT is significantly lighter than concrete and steel, making it easier to transport, handle, and install. This can lead to shorter construction times and reduced labor costs.

Design Flexibility: CLT can be custom-cut into various shapes and sizes, allowing for intricate and innovative architectural designs. It provides architects and builders with greater creative freedom to design unique and aesthetically pleasing structures. Thermal Insulation: CLT provides excellent thermal insulation properties, helping to create energy-efficient buildings. It can contribute to reduced heating and cooling costs and provide a comfortable indoor climate. Fire Resistance: While wood is generally perceived as flammable, CLT has inherent fire-resistant properties. The thick layers of wood char slowly when exposed to fire, creating a protective barrier that can maintain the structural integrity of the building. Acoustic Properties: CLT offers good acoustic performance, reducing sound transmission between rooms and floors. This makes it suitable for residential, commercial, and institutional buildings where noise control is essential. Rapid Construction: CLT panels are prefabricated off-site, which speeds up the construction process. This can result in shorter project timelines and cost savings. Less Disruption: Because CLT panels are assembled quickly, construction sites may have reduced noise and disruption, minimizing the impact on neighboring properties and the environment. Aesthetic Appeal: The natural wood finish of CLT panels can enhance the visual appeal of a building's interior. Exposed CLT surfaces often create warm and inviting spaces. Seismic Performance: CLT's excellent strength-to-weight ratio and ductile properties make it well-suited for earthquake-prone regions. It can withstand seismic forces and provide enhanced safety. Waste Reduction: CLT is manufactured with precision, minimizing waste during production. Additionally, wood waste generated during construction can be recycled or repurposed. These benefits make CLT an attractive choice for sustainable, efficient, and visually appealing construction projects, offering a viable alternative to traditional building materials.